2018 RULES

– THERE ARE NOW 2 STRUCTURAL CATEGORIES: Braced and Unbraced. The Braced division may use the vertical legs of the loading device, the Unbraced division may not. If, during loading, your bridge deflects enough to bear against the vertical legs of the loading device, IT WILL BE COMPETING IN THE BRACED DIVISION.

– Bridges must span a minimum of 24” between supports.

– The “eat your own bridge” policy will be enforced! Reasonable portions of your bridge will be chosen for you to consume.

– Structure will consist exclusively of gingerbread and/or graham cracker panels, and edible candy for tension cables and/or connections only. (Meaning, in a structural context: All steel/concrete members can only be gingerbread panels. Cable/tension members may be candy. Bolts/welds/connections of main members may be icing or candy)

– Candy decorations may be added, but may not be load bearing or structural (cables and connections exempt).

– No individual gingerbread/graham cracker member (panel) may exceed the dimensions of 8” x 4” x 3/4” (cables exempt).

– Bridges may not be solid (one member) in cross-section. They may be multiple ply adhered members so long as they comply with maximum panel dimensions.

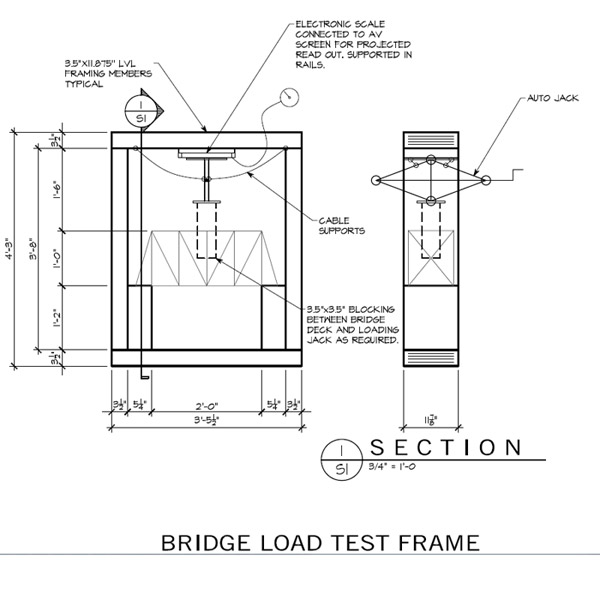

– The bridge’s deck must accommodate the loading mechanism (see pictures & drawings below for dimensions), and it must be horizontal across the 24” span. You are solely responsible for ensuring the compatibility of your bridge with the loading mechanism. Bridges without a conforming horizontal deck will have 25% of the bridge’s actual weight added to the Load/Weight calculation (5 lbs max)!!

– No bridge may exceed 12” tall or 6” in width.

– The bridge must fit within the test rig as shown.

– The bridge will have to support the weight of the testing jack prior to loading.

– The bridge may have removable “aesthetics” that will not be part of the bridge structure to be tested.

– Bridges failing before loading has begun will receive a Failure Load of 0 lbs.

– If you have any concerns about your bridge’s compatibility with either the rules or loading device, please do not hesitate to ask!

Loading procedure:

– Bridge contestants will place their bridge in the loading device with review by Test Monitors. Plastic bags of flour will be available to aid in supporting the bridge evenly over the bearing area.

– All bridges must be able to support a 3.5” x 3.5” square load applicator. Structural or non-structural portions of the bridge that cannot accommodate the test apparatus loading mechanism may suffer damage prior to loading being applied.

– The Bridge Weight will be determined by weighing with a separate scale.

– Bridge will be loaded to failure or extreme deflection.

– If the bridge capacity exceeds the loading ability of the test rig, its rating will be based upon its maximum test load as measured divided by its weight.

– Anything that is placed upon the test apparatus for bracing, shimming etc., as required to test the bridge entry, must be edible and will be added to the weight of the tested bridge with respect to strength-to-weight ratios, under which, a bridge winner will be determined. Nothing can be added to the test apparatus that would decrease the clear span of 24”.

LOADING MECHANISM

LOADING MECHANISM WEIGHTS:

Jack & attached OSB = 9.9lbs

Scale = 7.7lbs

Blocks:

12″ = 2.2lbs

9″ = 1.7lbs

6″ = 1.0lbs

3″ = 0.5lbs