Rules

2024 DENVER GINGERBREAD BRIDGE RULES

Bridge Constraints:

- No bridge may exceed 12” tall or 6” in width. The 12” dimension is an overall dimension; this is measured from the lowest point to the tallest point just prior to being put in the test rig.

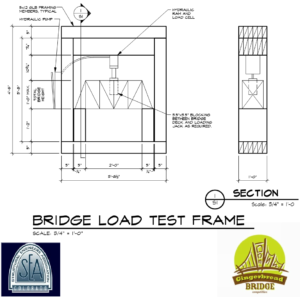

- Bridges must span a minimum of 24” between supports. Bridges should be greater than 24″ in length to allow for bearing on each end (we recommend 30″± to allow for sufficient bearing on each end). The maximum bridge length is 33″. See Bridge Load Test Frame diagram below for test rig layout.

- Structure will consist exclusively of gingerbread and/or graham cracker panels, and edible candy for tension cables and/or connections only. (Meaning, in a structural context: All steel/concrete members can only be gingerbread/graham cracker panels. Cable/tension members may be candy. Bolts/welds/connections of main members may be icing or candy. No precast elements.)

- No individual gingerbread/graham cracker panel may exceed the dimension of 8” x 4” x ¾” (cables exempt).

- Bridges may not be solid (one member) in cross-section. They may be multiple ply adhered members in either direction so long as they comply with maximum panel dimensions.

- Bridges, or portions of your bridge, are allowed to be coated/cover your bridge in your chosen panel adhering material (i.e. candy, chocolate, etc.) to assist with the joining of panels. Note that ‘precast panels’ where gingerbread has been broken up to act as an aggregate and poured into max. 8″x4″ shapes is NOT permitted.

- The bridge must fit within the test rig as shown.

- Bridge ends MAY NOT be braced by test rig vertical legs (i.e. no thrusting).

- The bridge’s deck must accommodate the loading mechanism/applicator (RE: loading procedure). You are solely responsible for ensuring the compatibility of your bridge with the loading mechanism.

- The bridge will have to support any wood spacers required to bring the ram into contact with the bridge prior to testing.

- Bridges must be self-supporting to earn a strength to weight ratio. Bridges failing before loading begins will receive a Failure Load = 0 lbs.

- Candy decorations may be added, but may not be load bearing or structural (cables and connections exempt).

- The “eat your own bridge” policy will be enforced! Reasonable portions of your bridge will be chosen for you to consume.

Architectural Display Constraints:

- The maximum size of the architectural display is 36″ long x 30″ deep. Primary public access will be along the long dimension of the display board. See display board figure below for additional information.

- All display components must be edible with the exception of 30” x 36” display board.

- A non-edible poster backdrop may be used. Backdrop width should not exceed maximum display length. Any posters or backdrops must be self-supporting.

- The bridge may have removable “architectural components” that will not be part of the bridge structure to be tested.

Loading Procedure:

- The bridge weight will be determined by weighing it on a digital scale.

- Bridge contestants will place their bridge in the loading device with review by Test Monitors. Plastic bags of flour will be available to help support the bridge evenly over the bearing area.

- All bridges must be able to support a 3.5” x 3.5” square load applicator. Structural or non-structural portions of the bridge that cannot accommodate the test apparatus loading mechanism may suffer damage prior to loading.

- A contestant from the team whose bridge is being tested will apply the load to the bridge (via the hydraulic ram) until failure occurs.

- If the bridge capacity exceeds the loading ability of the test rig, its rating will be based upon its maximum test load as measured divided by its weight.

If you have any concerns about your bridge’s compatibility with either the rules or loading device, please do not hesitate to contact the YMG Committee by emailing ymg@seacolorado.org!

LOADING MECHANISM WEIGHTS:

Spacer Blocks:

4x4x1′-0″ = 2.2lbs

4x4x0′-9″ = 1.7lbs

4x4x0′-6″ = 1.0lbs

4x4x0′-3″ = 0.5lbs

4x4x0′-1 1/4″ = 0.3lbs

4x4x0′-1 1/8″ = 0.2lbs

1x6x0′-5 3/4″ = 0.4lbs

Leveling Bags:

0.2-0.3lbs each